How We Can Help You

Campbell Scientific’s measurement automation platform has been created with 50 years of experience in the design and manufacturing of geotechnical monitoring and data-acquisition systems. Campbell Scientific is well recognized for monitoring platforms used globally in some of the most extreme and unforgiving environments on Earth. Each platform provides accuracy and reliability for critical applications, where human lives are often at stake. Simple interfaces, ease of setup, and long-term reliability make it the preferred platform for service providers in geotechnical monitoring applications.

- Reduce uncertainty. Built to reduce project uncertainty through automated measurements with data integrity, security, quality control, and local alarming capabilities

- Efficient operations. Built to make measurement automation setup and long-term operation simple and fast

- Scalable. From small, single projects to large-scale, multi-site operations

- Open ecosystem. Plug-and-play, self-configuring, and capable of interfacing with any sensor, Campbell Scientific allows you to own your data, own your network, and control your configuration.

- Data sharing. Powerful reporting, dashboard building, and built-in data sharing tools keep everyone informed. Designed for you and your stakeholders.

Measurement automation platforms are unique to each application because of the many types of measurements they are required to collect.

The versatility, ruggedness, and reliability of Campbell Scientific monitoring systems make them ideal for all geotechnical monitoring needs, including, but not limited to, water level, water quality, slope stability analysis, weather monitoring, ambient air quality, environmental compliance, dam and tailing monitoring, mine ventilation, and equipment performance.

In addition to real-time data measurement, each measurement device will alert you of changes in factors such as water level, load, pressure, and tilt if they move beyond acceptable ranges. Historical and real-time data can be transmitted directly to the cloud or to your PC. Measurement automation platforms are rugged, low power, and adaptable to the harshest, most remote environments.

Having a design that can operate in harsh, remote locations—where unsafe conditions are often not suitable for personnel—and be reliable enough to keep people safe is absolutely a necessity. Campbell Scientific automated monitoring systems provide many benefits:

- Reduced resources (work hours, fuel, safety risks) required to have personnel manually collect data from sensors

- Increased data availability (data available 24/7)

- Improved data integrity

- Better worker and public safety

- Ability to monitor critical parameters even during shutdown or long-term care and maintenance

- Cost-effective implementation of governance around environmental and safety solutions

Allow our team of experienced application engineers to make this easy as they help you build a monitoring system specific to the measurements you need.

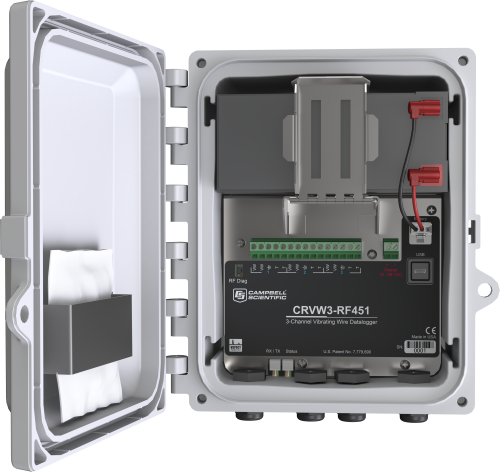

Learn about our patented VSPECT® spectral-analysis technology at our VSPECT Essentials web resource.

Learn about dynamic vibrating wire sensor measurements at our Dynamic Vibrating Wire web resource.

The dynamic vibrating wire measurement technique is protected under U.S. Patent No. 8,671,758, and the vibrating wire spectral-analysis technology (VSPECT) is protected under U.S. Patent No. 7,779,690.

Learn moreTo see how our systems meet your application needs, review our case studies »

Customize a System

In addition to our standard systems available, many of the systems we provide are customized. Tell us what you need, and we’ll help you configure a system that meets your exact needs.

More Details about Our Geotechnical Systems

Geotechnical Measurement Automation Platforms

The versatility of our platforms allows them to be customized for each application. We offer a range of platforms, from the most basic device with just a few channels to expandable platforms that measure hundreds of channels. Scan rates can be programmed from once every few hours to 10,000 times per second, depending on the model. Measurement types, processing algorithms, and recording intervals are also programmable.

The measurement automation platform has a simple, yet powerful on-board instruction set. Simply choose the sensor type, scan rate, and measurement channel. On-board mathematical and statistical processing allows data reduction in the field and enables measurements to be viewed in the desired units, whether that is microstrains, centimeters per second, revolutions per minute, meters, Amperes, or inches.

The versatility of the measurement automation platform extends to control as well. Each platform can monitor and control external devices based on time or measured conditions, allowing savings in time and equipment, and warning of—or possible prevention of—dangerous conditions. These platforms are rugged enough to be used in geotechnical sites worldwide.

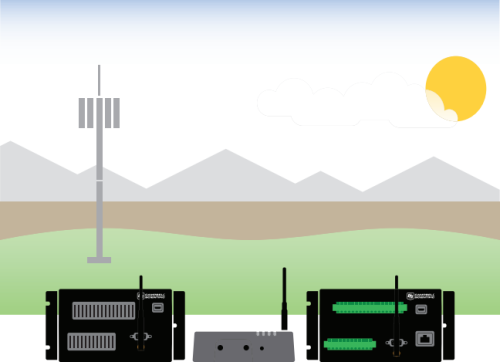

The measurement automation platform can stand alone. Once programmed and powered, no human or computer interaction is required, although data are typically downloaded to a PC or exported to the cloud for further analysis. A telecommunications or hardwire link allows data to be monitored and graphed in your office rather than in the field. Data from various stations and applications can be monitored from a single laptop or desktop computer.

The low power drain typically allows our platforms to be powered by solar panels and batteries. If 110/220-Vac power or external 12-Vdc batteries are available, you can use those as well. Nonvolatile data storage and a battery-backed clock ensure data capture and integrity.

Training

Campbell Scientific offers training courses that can be conducted at your location and customized to meet your specific needs. Hands-on training with our engineers helps ensure your system provides the site condition data you need today and into the future.

Sensors Used for Geotechnical Measurements

The flexibility of our measurement automation platforms begins with sensor compatibility. Our platforms can measure virtually every commercially available sensor, allowing them to be used in different ways for a variety of measurements. For example, the following are common parameters that the sensors in our platforms measure:

- Pore water pressure

- Water level

- Water flow

- Settlement

- Displacement

- Strain

- Tilt

- Inclination

- Weight

- Force

- Pressure

- Deflection

- Barometric pressure

- Temperature

- Humidity

- Elevation

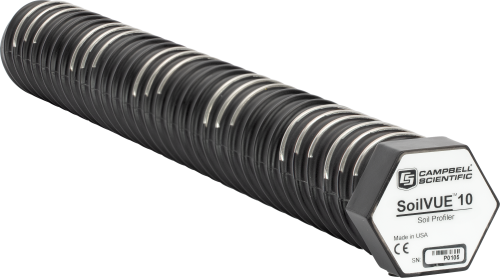

More specifically, these are the sensor types commonly used in our measurement automation platforms:

- Piezometers

- Pressure transducers

- Inclinometers

- Tiltmeters

- Settlement sensors

- Borehole pressure cells

- Earth pressure cells

- Load cells

- Pressure cells

- Accelerometers

- Vibrating wire strain gauges

- Foil-bonded strain gauges

- Extensometers

- Jointmeters

- Crackmeters

- Strainmeters

- Deformation meters

- Barometers

- Tilt beams

- Stressmeters

- Thermistors

- Thermocouples

- Deformation sensors

- Sonic water-level sensors

- Displacement transducers

- Linear variable differential transformers (LVDT)

Because our measurement automation platforms have many channel types and programmable inputs, all these sensor types can be measured by one device. Channel types include analog (single-ended and differential), pulse counter, switched excitation, continuous analog output, digital I/O, and anti-aliasing filter. Using switched or continuous excitation channels, our platforms provide excitation for ratiometric bridge measurements.

The following are common sensor measurement types that our measurement automation platforms are compatible with:

- Frequency

- Resistance

- Voltage

- Ratiometric

- Current

- Modbus RTU

- RS-485

- SDI-12

- RS-232

Communications

The availability of multiple communications options for retrieving, storing, and displaying data also allows platforms to be customized to meet your exact needs. Onsite communications options include direct connection to a PC or laptop, PC cards, storage modules, and platform keyboard/display. Telecommunications options include short-haul, telephone (including voice-synthesized and cellular), radio frequency, multidrop, and satellite.

Documents

Miscellaneous

Case Studies

The Expressway S19 represents a critical link in Europe’s transportation network, stretching 570 km (354.2......read more

In August 2012, RESPEC was contracted to provide field instrumentation and early-warning monitoring services at......read more

RESPEC, a water-resources consulting and services firm, is currently under contract to operate and maintain......read more

Integrators and Consultants

Upcoming Events

-

11th ICGSM

June 23-26, 2025 | Poppi, Italy

Articles and Press Releases

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences