How We Can Help You

Campbell Scientific data-acquisition systems are an important part of building structure projects. Our systems provide remote, unattended, portable monitoring for temperature, relative humidity, solar radiation, wind speed, wind direction, power consumption, water consumption, vibration, load, and pressures—all at multiple locations. They are compatible with a wide variety of sensors and peripherals to fit your exact needs.

Learn about our patented VSPECT® spectral-analysis technology at our VSPECT Essentials web resource.

The dynamic vibrating wire measurement technique is protected under U.S. Patent No. 8,671,758, and the vibrating wire spectral-analysis technology (VSPECT) is protected under U.S. Patent No. 7,779,690.

Learn moreTo see how our systems meet your application needs, review our case studies »

Customize a System

In addition to our standard systems available, many of the systems we provide are customized. Tell us what you need, and we’ll help you configure a system that meets your exact needs.

Related Product Categories

More Details about Our Building Structures Systems

Control Units

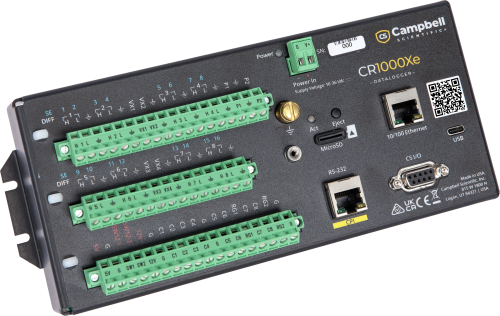

Our control units are programmable and provide advanced measurement and control. They perform the functions of a PLC and more.

The reliability of our control units ensures collection of time-stamped data, even under adverse circumstances. Because they have their own power supply (alkaline or rechargeable batteries), the control units continue to measure and record existing conditions during power outages. Up to 2 million data points can be stored onboard, depending on the model. Time-stamped data provides valuable information for identifying and verifying past events. In monitoring operations where temperatures or other parameters must be kept within specific ranges (to ensure the quality of products or equipment), historical data can provide important information. Harsh environments don't affect the reliability of our systems.

Statistical and mathematical functions are built into our units, allowing data reduction at the measurement site. Measurements can be processed and stored in the desired units of measure (i.e., °F, °C, psi, inches of water, inches of mercury, etc.).

Measurement Capabilities

Each control unit has multiple channel types, allowing nearly all sensor types to be measured by a single unit. For example, one control unit can measure voltage, air velocities, air temperature, relative humidity, energy use, water temperature, and steam pressure, as well as solar radiation, external temperature, wind speed, and air quality. Channel types include analog (single-ended and differential), pulse, digital I/O, and switched excitation. Most sensors connect directly to the control units, eliminating external signal conditioning. Multiplexers and other peripherals can be used to increase the number of channels and channel types.

Control Capabilities

Because our control units are programmable (without ladder logic), they can perform responsive measurement and control sequences. Powerful on-board instruction sets allow unattended measurement and control decisions based on time or conditional events. For example, alarms can be triggered, phone numbers dialed, or equipment shut down if a boiler's water temperature is outside the desired range. Our systems can even perform control based on multiple conditions or events, such as deciding to increase or decrease air exchange based on time of day, outside temperature, and/or inside temperature.

Sensors

Almost any sensor may be used with the system, allowing customization for each operation. Each of our control units features a variety of channel types for flexibility in measuring many different types of sensors.

Communications

Communications options for reporting site conditions include:

- ethernet

- coaxial cable

- radio

- telephone

- cellphone

- voice-synthesized phone

The system can be monitored and controlled by an on-site or remote computer. You can even post your data on the Internet.

Example Application

In a typical HVAC application, sensors monitor relative humidity, flow rates, indoor temperature, outdoor temperature, differential pressures, and equipment status. In smaller operations, only one control unit is needed. When a large number of sensors are used or when there are many monitoring locations, additional control units are used. Based on the measurements and the desired outcome, the control units actuate proportioning valves, boilers, heat exchange units, pumps, blowers, air handlers and other devices required to bring building(s) to the desired state. In case of equipment failure (or other measured event), the system sounds alarms or calls out on a phone, radio, cellphone, or other device. Data can be stored and/or transmitted to an on-site or central computer.

Documents

Technical Papers

Case Studies

The Problem The Lakhta Tower is a building that was completed in 2018, designed for both......read more

The Problem—How to optimize green-roof performance The University of Toronto's Green Roof Innovation Testing Laboratory (GRIT......read more

In 1922, when the intact tomb of Tutankhamen was discovered in Egypt's Valley of the......read more

The 385-acre Chicago Botanic Garden welcomes more than 750,000 visitors each year. Its new Daniel......read more

The Solar Decathlon takes place every other year on the National Mall in Washington, D.C.......read more

Campbell Scientific and Geo-Watersheds Scientific are research partners with the Cold Climate Housing Research Center......read more

Jordan Commons in southern Dade County is an innovative, energyefficient housing development being constructed for......read more

A Campbell Scientific data logger is being used by the The National Association of Home......read more

Frequently Asked Questions

Number of FAQs related to Building Structures: 1

-

Most Campbell Scientific systems are built from individual components. This provides maximum flexibility for our customers, but it does not lend itself to pricing a "typical" system. Contact Campbell Scientific for assistance in pricing a system to meet the unique needs of the application.

Integrators and Consultants

Associated Links

Articles and Press Releases

Newsletter Articles

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences